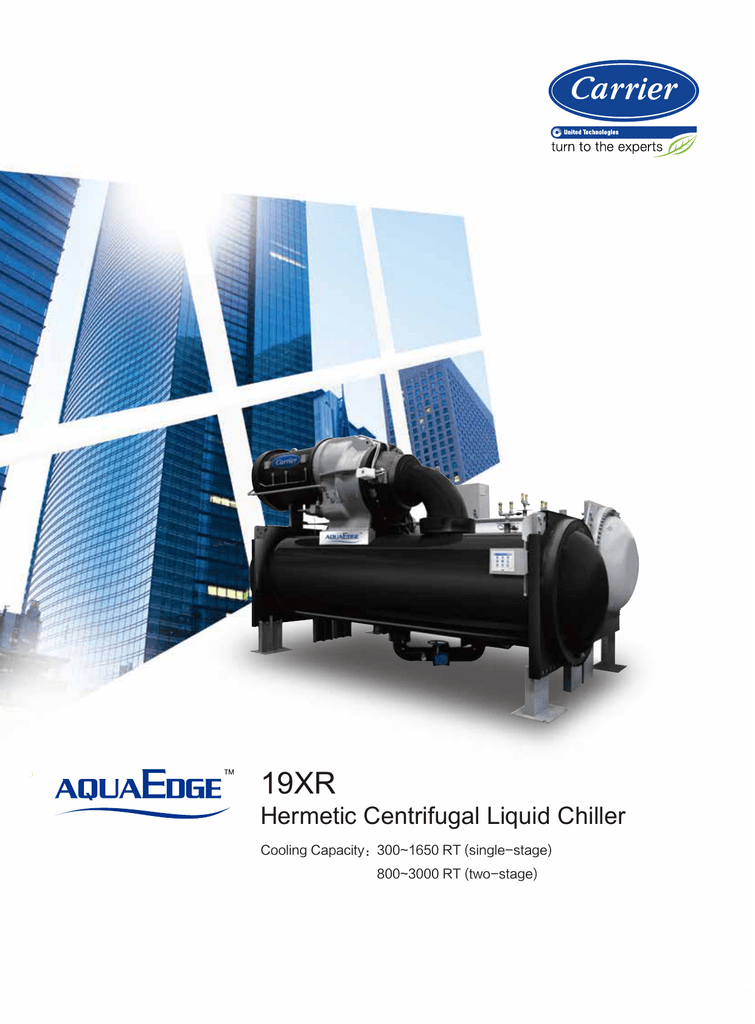

Carrier 19XR Centrifugal water-cooled high efficiency liquid chiller with R-134a refrigerant provides superior full- and part-load effciencies. Press Release - Carrier® SMART Service Delivers Enhanced Chiller Performance; Press Release - Carrier AquaEdge® 19XR, 23XR and AquaForce® 30XV and XA Chillers are Available With Lower Global. 19XR PIC II/19XRV PIC III Hermetic Centrifugal Liquid Chillers Nominal cooling capacity 1000 - 5300 kW 50 Hz Installation, operation and maintenance instructions.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53190012-01

Printed in U.S.A.

Form 19XRV-3SS

Pg 1

Carrier 19xr Maintenance Manual

711 3-11

Replaces: New

Start-Up and Service Instructions

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe and

reliable service when operated within design specifica-

tions. When operating this equipment, use good judgment

and safety precautions to avoid damage to equipment and

property or injury to personnel.

Navision provides the flexibility to set up your system for today’s business requirements, as well as a reliable platform for change and growth. Dynamics nav 2018 manual. Meet changing business needs without disrupting your or your IT budget and make the most of your current IT investments. Benefits. Maximize Your Technology Post-ImplementationOngoing help is provided by our partners for all customers; whatever your NAV training needs, it can be delivered.The Microsoft Dynamics NAV training program with its robust, classifies and assists productivity enhancement at enterprise level. Fast to implement, easy to configure and simple to use.

Be sure you understand and follow the procedures and

safety precautions contained in the chiller instructions as

well as those listed in this guide.

ONLY QUALIFIED Electrical Personnel familiar with the construction

and operation of this equipment and the hazards involved should install,

adjust, operate, or service this equipment.

READ AND UNDERSTAND this manual and other applicable manuals in

their entirety before proceeding. Failure to observe this precaution could

result in severe bodily injury or loss of life.

DO NOT install modification kits with power applied to the drive. Discon-

nect and lock out incoming power before attempting such installation or

removal. Failure to observe this precaution could result in severe bodily

injury or loss of life

UNUSED WIRES in conduit must be grounded at both ends to avoid a

possible shock hazard caused by induced voltages. Also, if a drive sharing

a conduit is being serviced or installed; all drives using this conduit should

Vlc media player for download. be disabled to eliminate the possible shock hazard from cross-coupled

motor leads. Failure to observe these precautions could result in bodily

injury.

DO NOT VENT refrigerant relief valves within a building. Outlet from

rupture disc or relief valve must be vented outdoors in accordance with the

latest edition of ANSI/ASHRAE 15 (American National Standards Insti-

tute/American Society of Heating, Refrigerating, and Air Conditioning

Engineers). The accumulation of refrigerant in an enclosed space can dis-

place oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ANSI/ASHRAE 15,

especially for enclosed and low overhead spaces. Inhalation of high con-

centrations of vapor is harmful and may cause heart irregularities, uncon-

sciousness, or death. Misuse can be fatal. Vapor is heavier than air and

reduces the amount of oxygen available for breathing. Product causes eye

and skin irritation. Decomposition products are hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a chiller for any

purpose. Oxygen gas reacts violently with oil, grease, and other common

substances.

NEVER EXCEED specified test pressures, VERIFY the allowable test

pressure by checking the instruction literature and the design pressures on

the equipment nameplate.

DO NOT USE air for leak testing. Use only refrigerant or dry nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and func-

tioning before operating any chiller.

THERE IS A RISK OF INJURY OR DEATH by electrocution. High volt-

age may be present on the motor leads even though the motor is not run-

ning. Open the power supply disconnect before touching motor leads or

terminals.

DO NOT WELD OR FLAMECUT any refrigerant line or vessel until all

refrigerant (liquid and vapor) has been removed from chiller. Traces of

vapor should be displaced with dry air or nitrogen and the work area

should be well ventilated. Refrigerant in contact with an open flame pro-

duces toxic gases.

DO NOT work on high-voltage equipment unless you are a qualified elec-

trician.

DO NOT WORK ON electrical components, including control panels,

switches, VFD, or oil heater until you are sure ALL POWER IS OFF and

no residual voltage can leak from capacitors or solid-state components.

LOCK OPEN AND TAG electrical circuits during servicing. IF WORK IS

INTERRUPTED, confirm that all circuits are deenergized before resuming

work.

AVOID SPILLING liquid refrigerant on skin or getting it into the eyes.

USE SAFETY GOGGLES. Wash any spills from the skin with soap and

water. If liquid refrigerant enters the eyes, IMMEDIATELY FLUSH EYES

with water and consult a physician.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while chiller is

under pressure or while chiller is running. Be sure pressure is at 0 psig (0

kPa) before breaking any refrigerant connection.

TO AVOID an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing. Check the DC bus

voltage at the Power Terminal Block by measuring between the +DC and -

DC terminals, between the +DC terminal and the chassis, and between the

-DC terminal and the chassis. The voltage must be zero for all three mea-

surements.

THE USER is responsible to conform with all applicable local, national,

and international codes. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

THIS DRIVE contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if

ESD control procedures are not followed. For static control procedures,

reference Rockwell publication Guarding Against Electrostatic Damage, or

any other applicable ESD protection handbook.

DO NOT alter the setting of any jumper. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

USE OF power correction capacitors on the output of the drive can result

in erratic operation of the motor, nuisance tripping, and/or permanent dam-

age to the drive. Remove power correction capacitors before proceeding.

Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

MOST CODES require that upstream branch circuit protection be pro-

vided to protect input power wiring. If fuses are chosen as the protection

method, refer to the PowerFlex 750 user manual. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

DO NOT route signal and control wiring with power wiring in the same

conduit. This can cause interference with drive operation. Failure to

observe this precaution could result in damage to, or destruction of, the

equipment.

DISTRIBUTION SYSTEM short circuit capacity shall not exceed the rat-

ing of the drive. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

DO NOT STEP on refrigerant lines. Broken lines can whip about and

release refrigerant, causing personal injury.

DO NOT climb over a chiller. Use platform, catwalk, or staging. Follow

safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or move

inspection covers or other heavy components. Even if components are

light, use mechanical equipment when there is a risk of slipping or losing

your balance.

BE AWARE that certain automatic start arrangements CAN ENGAGE

THE VFD, TOWER FAN, OR PUMPS. Open the disconnect ahead of the

VFD, tower fans, or pumps.

USE only repair or replacement parts that meet the code requirements of

the original equipment.

PERIODICALLY INSPECT all valves, fittings, and piping for corrosion,

rust, leaks, or damage.

DANGER

WARNING

CAUTION

19XRV

with PIC III Controls

Rockwell PowerFlex 755 VFD Option

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 211

Catalog No. 531-982

Printed in U.S.A.

Form 19XR-5SS

Pg 1

6-01

Replaces: 19XR-4SS

Book 2

Tab

5a

Start-Up, Operation, and Maintenance Instructions

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe and

reliable service when operated within design specifica-

tions. When operating this equipment, use good judgment

and safety precautions to avoid damage to equipment and

property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in the chiller instructions as

well as those listed in this guide.

DO NOT VENT refrigerant relief valves within a building. Outlet

from rupture disc or relief valve must be vented outdoors in accor-

dance with the latest edition of ANSI/ASHRAE 15 (American

National Standards Institute/American Society of Heating, Refrigera-

tion, and Air Conditioning Engineers). The accumulation of refriger-

ant in an enclosed space can displace oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ANSI/ASHRAE

15, especially for enclosed and low overhead spaces. Inhalation of

high concentrations of vapor is harmful and may cause heart irregular-

ities, unconsciousness, or death. Misuse can be fatal. Vapor is heavier

than air and reduces the amount of oxygen available for breathing.

Product causes eye and skin irritation. Decomposition products are

hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a chiller for

any purpose. Oxygen gas reacts violently with oil, grease, and other

common substances.

NEVER EXCEED specified test pressures, VERIFY the allowable

test pressure by checking the instruction literature and the design pres-

sures on the equipment nameplate.

DO NOT USE air for leak testing. Use only refrigerant or dry

nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and

functioning before operating any chiller.

RISK OF INJURY OR DEATH by electrocution. High voltage is

present on motor leads even though the motor is not running when a

solid-state or inside-delta mechanical starter is used. Open the power

supply disconnect before touching motor leads or terminal

s.

D

O NOT WELD OR FLAMECUT any refrigerant line or vessel until

all refrigerant (liquid and vapor) has been removed from chiller.

Traces of vapor should be displaced with dry air or nitrogen and the

work area should be well ventilated. Refrigerant in contact with an

open flame produces toxic gases.

DO NOT USE eyebolts or eyebolt holes to rig chiller sections or the

entire assembly.

DO NOT work on high-voltage equipment unless you are a qualified

electrician.

DO NOT WORK ON electrical components, including control pan-

els, switches, starters, or oil heater until you are sure ALL POWER IS

OFF and no residual voltage can leak from capacitors or solid-state

components.

LOCK OPEN AND TAG electrical circuits during servicing. IF

WORK IS INTERRUPTED, confirm that all circuits are deenergized

before resuming work.

AVOID SPILLING liquid refrigerant on skin or getting it into the

eyes. USE SAFETY GOGGLES. Wash any spills from the skin with

soap and water. If liquid refrigerant enters the eyes, IMMEDIATELY

FLUSH EYES with water and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cylinder.

Dangerous over pressure can result. When it is necessary to heat

refrigerant, use only warm (110 F [43 C]) water.

DO NOT REUSE disposable (nonreturnable) cylinders or attempt to

refill them. It is DANGEROUS AND ILLEGAL. When cylinder is

emptied, evacuate remaining gas pressure, loosen the collar and

unscrew and discard the valve stem. DO NOT INCINERATE.

CHECK THE REFRIGERANT TYPE before adding refrigerant to

the chiller. The introduction of the wrong refrigerant can cause dam-

age or malfunction to this chiller.

Operation of this equipment with refrigerants other than those

Carrier 19xr Service Manual Free

cited herein should comply with ANSI/ASHRAE 15 (latest edition).

Contact Carrier for further information on use of this chiller with other

refrigerants.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while

chiller is under pressure or while chiller is running. Be sure pressure is

at 0 psig (0 kPa) before breaking any refrigerant connection.

CAREFULLY INSPECT all relief devices, rupture discs, and other

relief devices AT LEAST ONCE A YEAR. If chiller operates in a

corrosive atmosphere, inspect the devices at more frequent intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION any relief

device when corrosion or build-up of foreign material (rust, dirt, scale,

etc.) is found within the valve body or mechanism. Replace the

device.

DO NOT install relief devices in series or backwards.

USE CARE when working near or in line with a compressed spring.

Sudden release of the spring can cause it and objects in its path to act

as projectiles.

DO NOT STEP on refrigerant lines. Broken lines can whip about and

release refrigerant, causing personal injury.

DO NOT climb over a chiller. Use platform, catwalk, or staging. Fol-

low safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or

move inspection covers or other heavy components. Even if compo-

nents are light, use mechanical equipment when there is a risk of slip-

ping or losing your balance.

BE AWARE that certain automatic start arrangements CAN

ENGAGE THE STARTER, TOWER FAN, OR PUMPS. Open the

disconnect ahead of the starter, tower fans, or pumps.

USE only repair or replacement parts that meet the code requirements

of the original equipment.

DO NOT VENT OR DRAIN waterboxes containing industrial brines,

liquid, gases, or semisolids without the permission of your process

control group.

DO NOT LOOSEN waterbox cover bolts until the waterbox has been

completely drained.

DOUBLE-CHECK that coupling nut wrenches, dial indicators, or

other items have been removed before rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking that the nut

has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping for corro-

sion, rust, leaks, or damage.

PROVIDE A DRAIN connection in the vent line near each pressure

relief device to prevent a build-up of condensate or

rain water.

19XR,XRV

Hermetic Centrifugal Liquid Chillers

50/60 Hz

With PIC II Controls and HFC-134a